MueTec develops high precision, optical measurement and inspection solutions that help customers in the semiconductor and microelectronics industries to improve their manufacturing yield and overall process control. Our team of technical experts listen to, respond to and anticipate the needs of wafer, reticle and MEMS manufacturers worldwide, offering customized and standard solutions at extremely low maintenance requirements. Scalable systems allow for a combination of many different applications in a single system, including critical dimension, overlay and film thickness measurement as well as defect inspection and review. Over the last 20 years, MueTec has installed 300 measurement and inspection systems around the world.

Inspection Products

Closed Frame Tools

ARGOS 200-F SiC

Used in: BACK - END

Key Differences: F=Frame; SiC = Silicon Carbide Technology

Key Features: Macro Defect Inspection; Optimized for SiC material

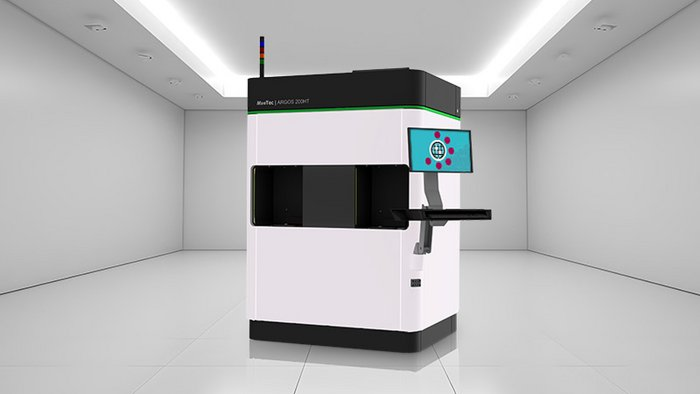

ARGOS 150HT / 200HT

Used in:

Front - END (Lithography)

Key Differences: HT = High Throughput

Key Features: Simultaneous wafer handling from 2 open cassette ports for high throughput; Small footprint; Recipeless operation

ARGOS 200-F / 300-F

Used in: Back - END

Key Differences:

Handling of framed wafer, fully SECS/GEM 300 compliant

Key Features:

Post-Sawn framed wafer inspection; 200mm or 300mm framed wafer handling; Recipeless operation

ARGOS 200 / 300

Used in:

Front - END (Lithography)

Key Differences:

200 or 300 mm Wafer

Key Features:

Macro Defect Inspection; FOUP based handling

Open Frame Tools

SPECTOR-A

Used in: Front - END

Key Differences:

Fully-automated for mask sizes up to 9"

Key Features:

Defect inspection from masks; Recipeless operation

SPECTOR-M

Used in: Front - END

Key Differences:

Semi-automated for mask sizes up to 9"

Key Features:

Defect inspection from masks;

Recipeless

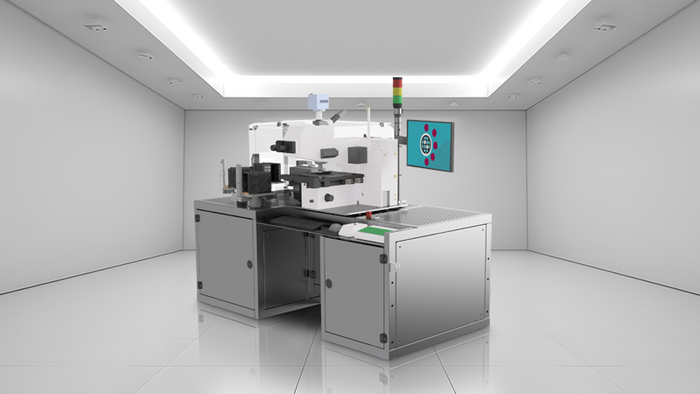

IRIS 2100

Used in: Front - END

Key Differences:

Fully-automated for wafer sizes up to 200mm

Key Features:

Metrology and Inspection from wafer with visible and infrared illuminations

Metrology Products

Closed Frame Tools

DaVinci 300 iOVL

Used in: Front - END

Key Differences: Tool for 300mm wafer

Key Features:

Metrology (overlay, critical dimension) - optimized for overlay measurement; 90nm node

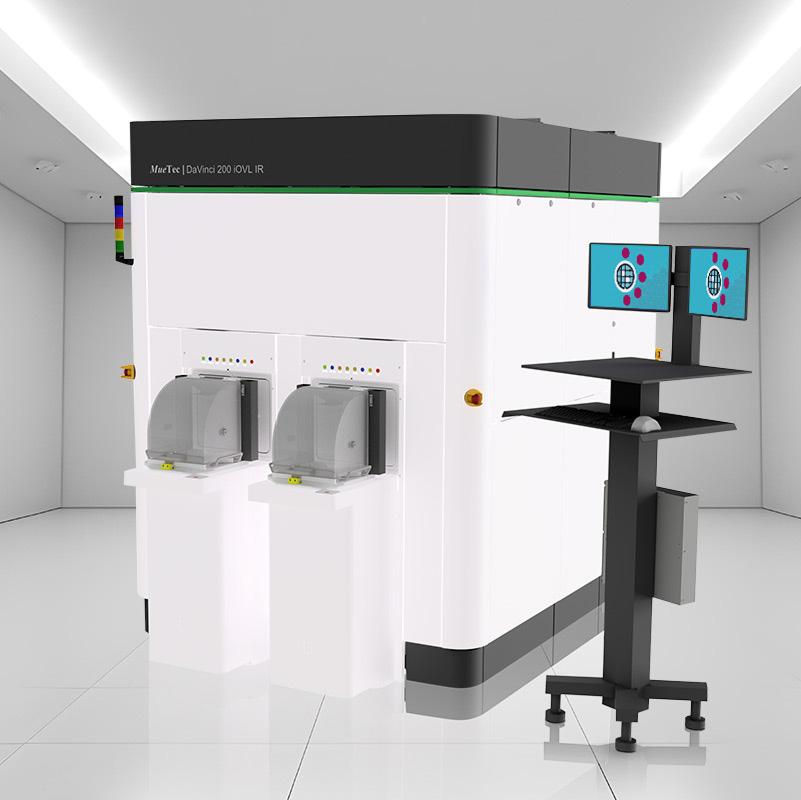

DaVinci 200 iOVL

Used in: Front - END

Key Differences: Tool for 200mm wafer

Key Features:

Metrology (overlay, critical dimension) - optimized for overlay measurement; 130nm node

DaVinci 150/200

Used in: Front - END

Key Differences: Tool for 150mm or 200mm Wafer

Key Features:

Metrology (overlay, critical dimension); film thickness measurement

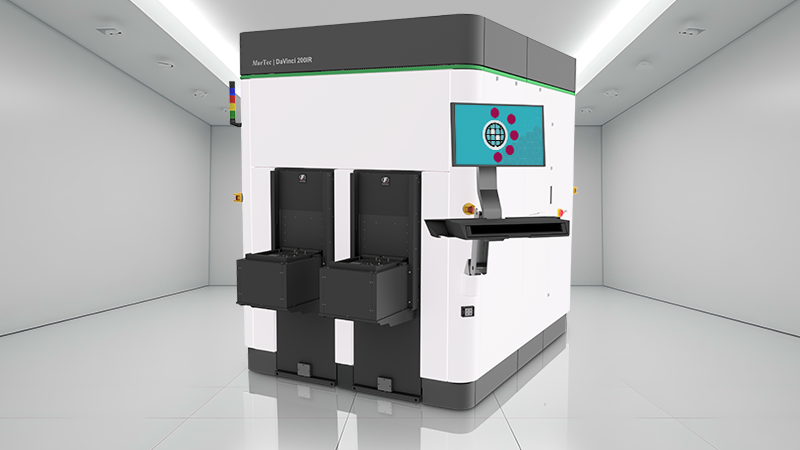

DaVinci 200IR/300IR

Used in: Front - END

Key Differences: Fully automated infrared tool for wafer sizes up to 300 mm

Key Features:

Metrology (Critical Dimension and overlay) for wafer; Visible and infrared Illumination; for mems wafer with high doping levels

Open Frame Tools

MT 3000VIS/UV

Used in: Front - END

Key Differences: Fully-automated for wafer sizes up to 200mm

Key Features:

Metrology (overlay, critical dimension) and inspection with visible and UV illumination; film thickness measurement

MT 2010

Used in: Front - END

Key Differences: Semi-automated for wafer sizes up to 200mm

Key Features:

Metrology (overlay, critical dimension) with visible illumination; film thickness measurement

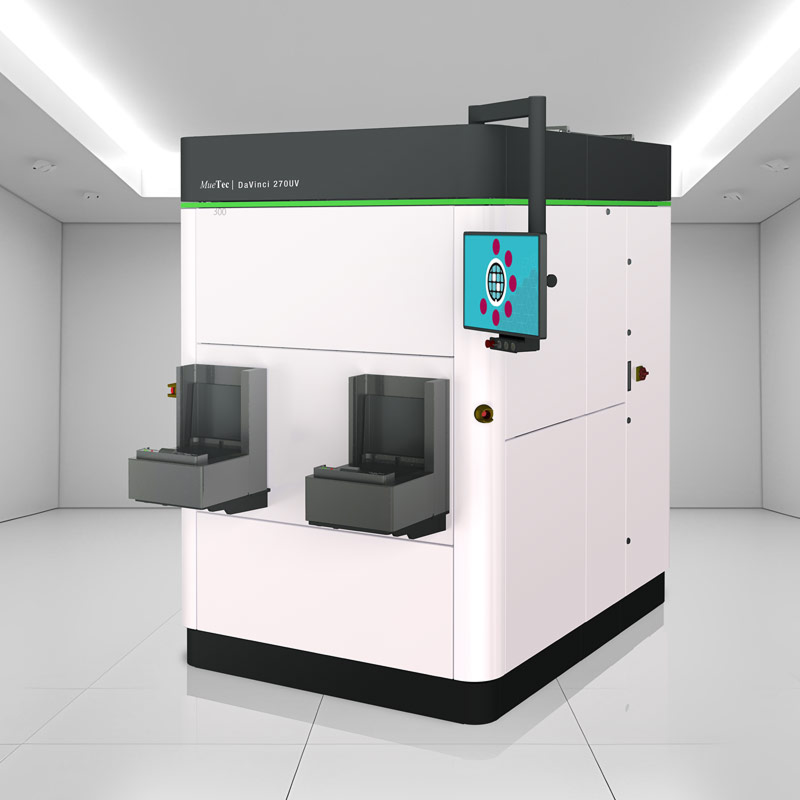

MT 270UV

Used in: Front - END

Key Differences: Semi-automated for Mask sizes up to 9"

Key Features:

CD-measurements on masks with visible and UV-illumination.

Customised Solutions

Almost every tool is customised

As part of our business model, we serve customers who need metrology and inspection solutions that do not exist in the market. Our dedicated group of mechanical engineers, software developers and application engineers listen to your requirements and come up with proposals to solve your challenge.

Examples for customised solutions include fully automated metrology and inspection systems for large area substrates as long as 4 meters in length, as well as customised handling systems or tools that combine different measurment and inspection functions in one system. Customised solutions represent an important pillar of our business ever since the founding of the company at the beginning of the 1990s.

Examples

SPECTOR 5500

Used in: Front - END

Key Differences: Closed Frame Tool; Mask Defect inspection

Key Features:

Mikro defekt inspection on Masks

Rembrandt 200 / 300

Used in: Front-END and Back-End

Key Differences: Closed Frame Tool; TOOL FOR Wafer Imaging

Key Features:

Wafer Micro Imaging

DaVinci 270UV

Used in: Front - END

Key Differences: Closed Frame Tool; Mask CD Metrology

Key Features:

CD Measurement on Mask

Comprehensive Service. Optimal Performance.

Our specialized service technicians will be on site for

- tool installations

- undertaking maintenance

- tool repairs

- service trainings

Our highly competent service team creates quotes for

- spare parts only contracts

- full service contracts with guaranteed response times and dedicated spare parts

- tool upgrades