Securing diversified business areas based on differentiated products and becoming a leader in new markets

Based on the original core technology of ALD technology in the time/space division method

"Low Temperature/Precise Control & Vacuum/Non-Vacuum High Productivity Time/Space Division ALD"

"Normal Pressure R2R & Powder ALD"

"Mixed ALD for Power Semiconductors"

Memory & System IC & Power: DRAM/NAND Capacitor, TSV, Stacking, etc. High Step coverage & Unif., Impurity Free Layer and GaOx Epi for next-generation power semiconductors. deposition

Li-ion Battery & Energy: Passivation layer such as cathode materials and separators & perovskite solar cells to improve charging and discharging efficiency of Li-ion batteries

OLED & Flexible/AR/VR Display: Low-temperature/precise composition control passivation such as Flexible, Micro LED, and Micro OLED for AR/VR, and OLED next-generation channel layer (oxide semiconductor, IGZO) deposition

3D/2D & Powder Coating: Functional layer and powder coating , such as improvement of heat resistance and corrosion resistance of showerhead and other parts in deposition and etching chamber, and modification of surface properties such as 2D film

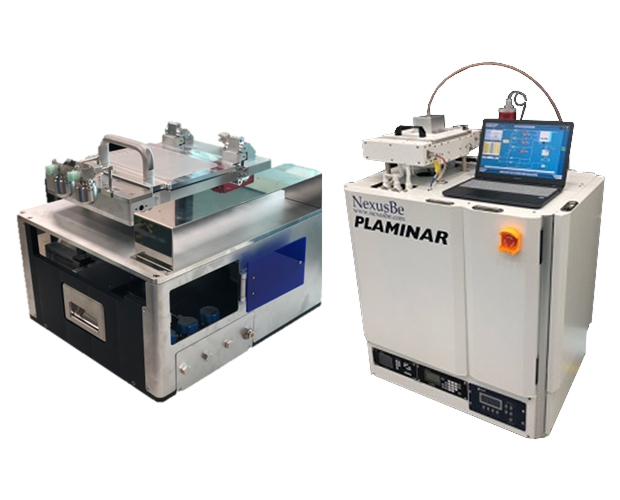

Products Line up

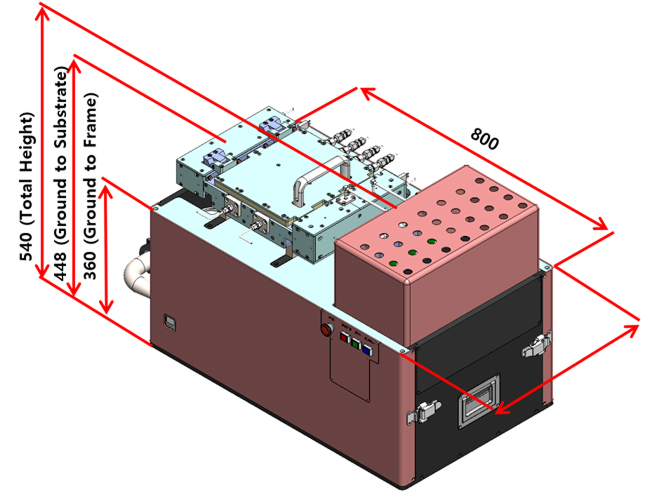

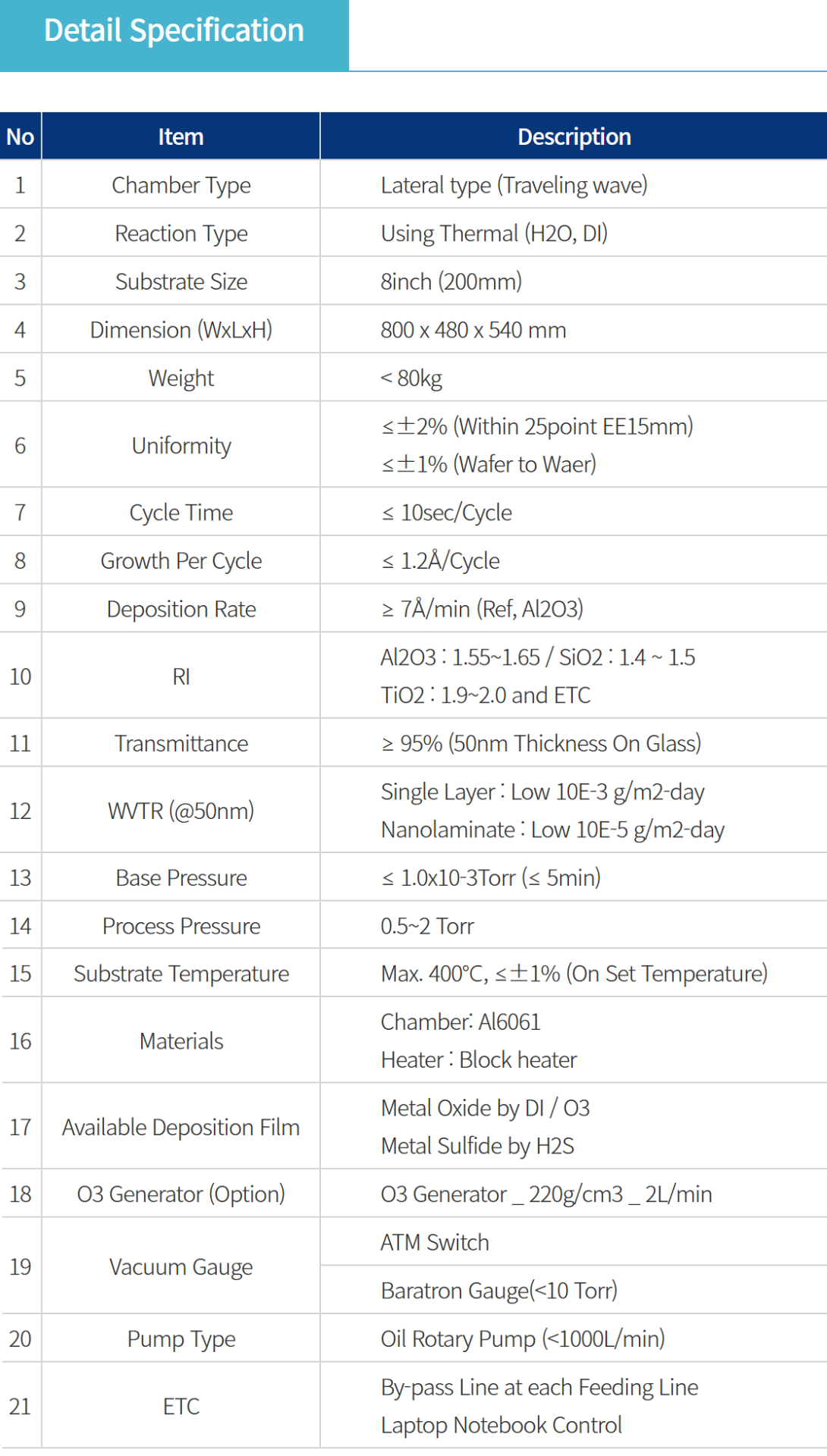

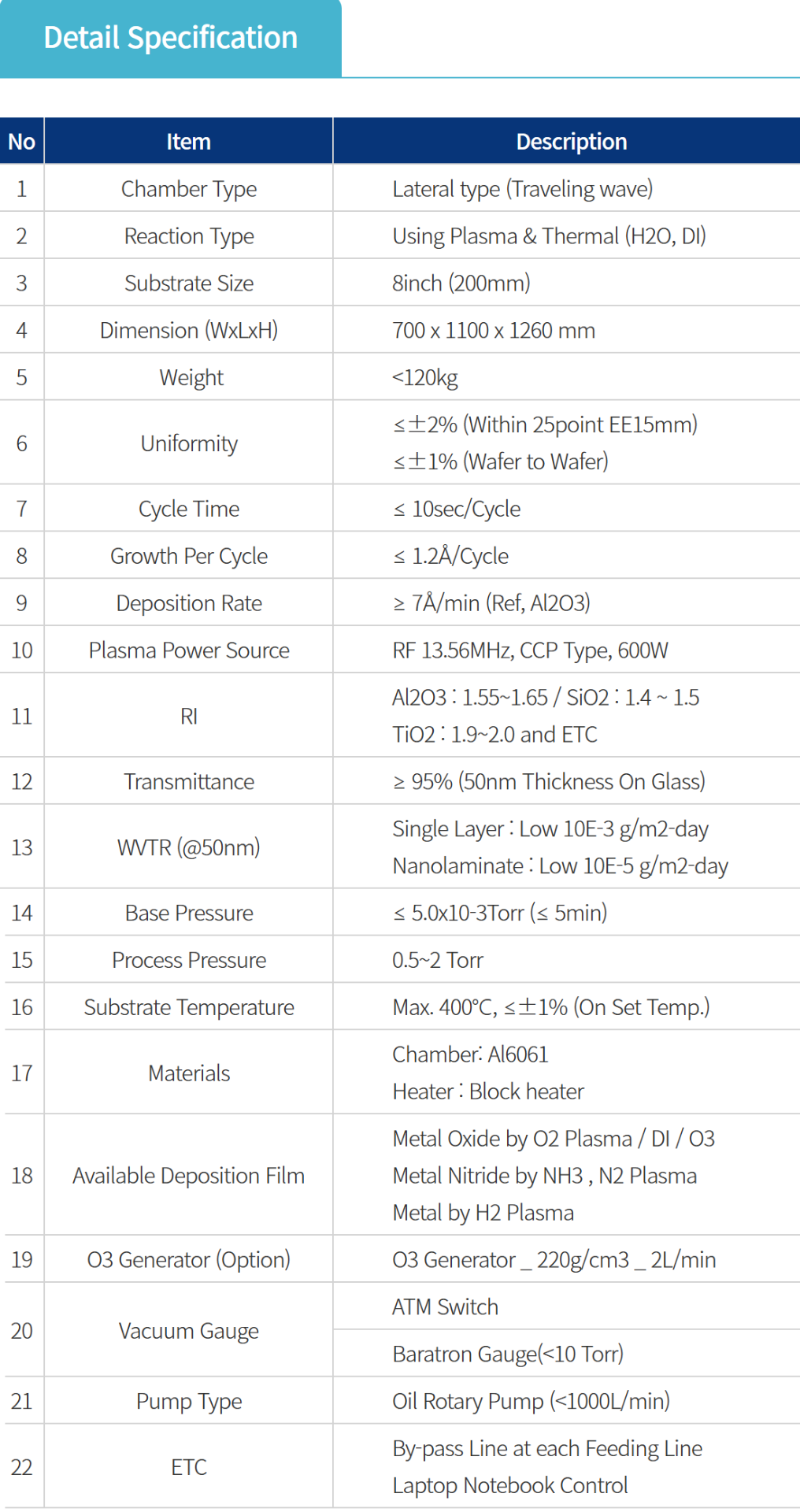

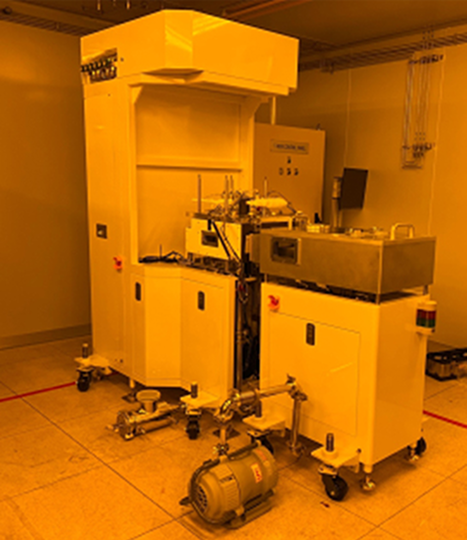

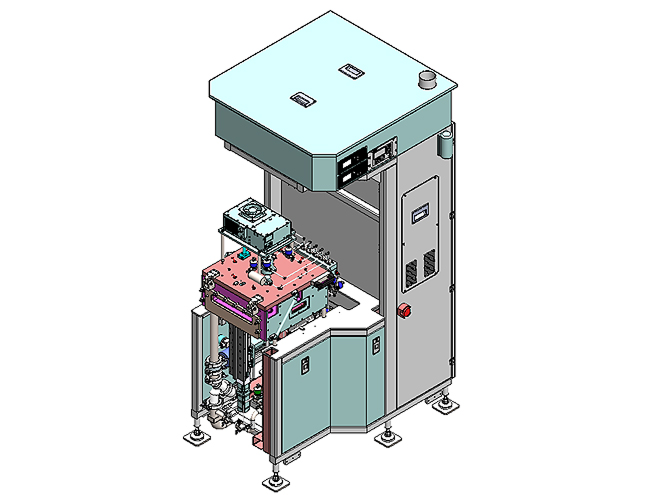

Nexus Mini ALD

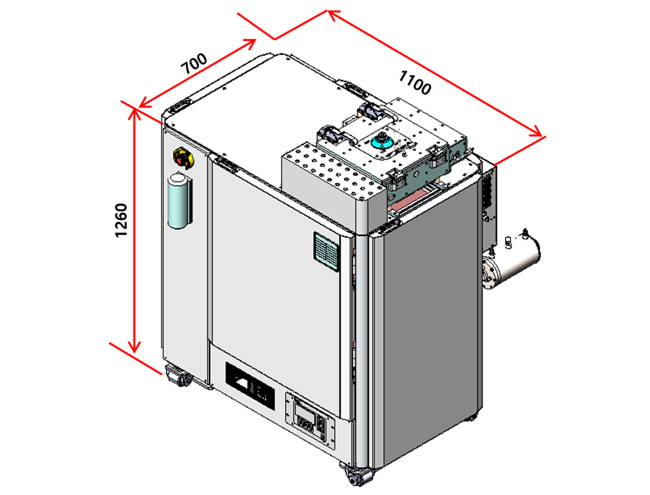

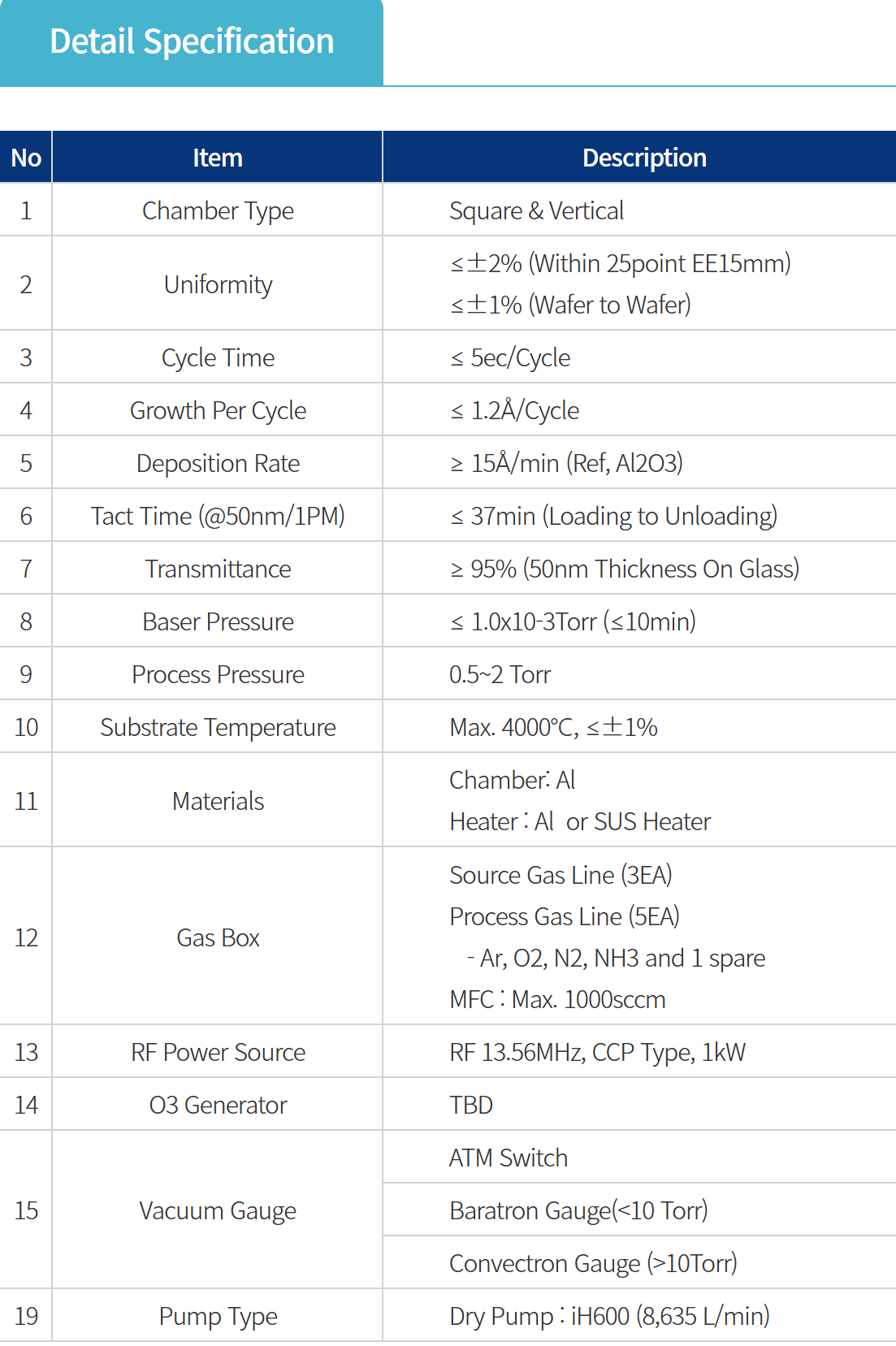

Nexus T-Max PEALD

Nexus Spatial ALD

1. Thermal Mini ALD

- Laminar Flow Type

- Single Type Thermal

- Load Lock & Cluster System

2. Plasma Mini ALD

1. Plasma Enhanced ALD

- Showerhead Gas Injection Type

- 12" Wafer or 200x200mm2 Glass

- Cluster System

2. O3 Based Thermal ALD

1. Spatial ALD

- Gas Injector Type

- 2G & 200x200mm2

- O3 Based Thermal

2. Atmospheric Spatial ALD & R2R ALD